Download this article in PDF format.

With supply chains across most industry sectors impacted by the global pandemic, the Cybersecurity & Infrastructure Security Agency (CISA) drilled down into the information technology and communication (ICT) sector to better understand those impacts and come up with some solutions to those problems. And while CISA’s recommendations directly address ICT, other industry sectors can also benefit from its observations and advice.

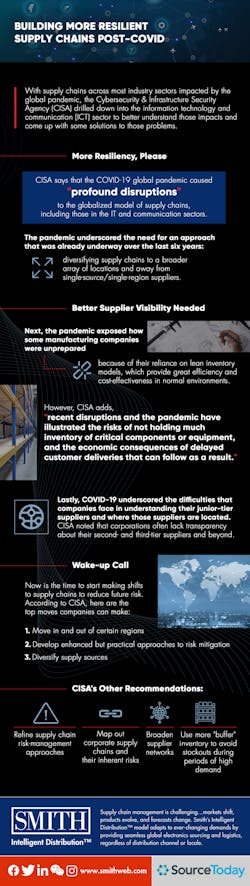

More Resiliency, Please

In “Building a More Resilient ICT Supply Chain: Lessons Learned During the Covid-19 Pandemic,” CISA says that the COVID-19 global pandemic caused “profound disruptions” to the globalized model of supply chains, including those in the IT and communication sectors. It explains how the global supply chain model constitutes sequential, multi-country production, where value is added in fragments along the way and where the country of origin is often difficult to determine.

“To that end,” CISA points out, “a product may be designed in New York, built in Vietnam, tested in Taiwan, stored in Hong Kong, sent to China for final assembly, and distributed globally to end customers for use.” In studying the behavior of those supply chains over the last several months, CISA says the pandemic underscored the need for an approach that was already underway over the last six years: diversifying supply chains to a broader array of locations and away from single source/single region suppliers.

“Indeed, many companies are moving production out of China in order to diversify supply chain locations due in part to the trade dispute between Washington and Beijing that reached its pinnacle last year,” CISA states. “Now, in some cases, COVID-19 is expediting that trend.”

Better Supplier Visibility Needed

Next, the pandemic exposed how some manufacturing companies were unprepared because of their reliance on lean inventory models, which provide great efficiency and cost-effectiveness in normal environments. However, CISA adds, “recent disruptions and the pandemic have illustrated the risks of not holding much inventory of critical components or equipment, and the economic consequences of delayed customer deliveries that can follow as a result.”

Lastly, COVID-19 underscored the difficulties that companies face in understanding their junior tier suppliers and where those suppliers are located. “While corporations know who they directly purchase equipment or components from (their Tier 1 suppliers), they often can lack transparency about their second and third tier suppliers and beyond,” CISA observes.

“Given that a single product can require hundreds of suppliers to make and assemble the finished product,” it continues, “the challenges of understanding these suppliers is a daunting and expensive proposition.”

Wake-up Call

CISA says that while the pandemic has been a wake-up call for many companies in the ICT sector, now is the time to start making shifts to supply chains in order to reduce future risk. It sees moving in and out of certain regions; developing enhanced but practical approaches to risk mitigation; and diversifying supply sources as a few of the top moves that companies can be making now.

“Given the global supply chain difficulties ICT companies are currently encountering because the virus adversely affects their ability to compress their cycle time,” CISA says, “there are active policy discussions as to whether firms should be provided with various incentives to bring manufacturing home, closer to home, or to never leave in the first place.”

CISA’s other recommendations for building supply chain resiliency in the post-COVID world include refining supply chain risk management approaches, mapping out corporate supply chains (and the inherent risk that exists in those networks), broadening out supplier networks and using more “buffer” inventory to avoid stockouts during periods of high demand.