Download this article in PDF format.

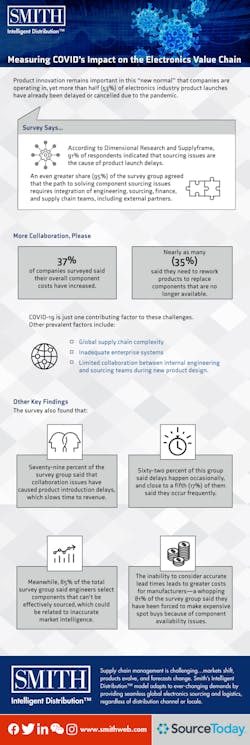

Product innovation remains important in this “new normal” that companies are operating in, yet more than half (53%) of electronics industry product launches have already been delayed or cancelled due to the pandemic, according to a new report from Dimensional Research and Supplyframe.

In “2020 Trends in Electronics Sourcing,” the companies say COVID-19 also has led to increased component costs, the need for manufacturers relying on the global electronics value chain to rework their products and the inability to fill customer orders. “That is especially problematic now,” they say, “in a challenging economy that has increased the importance of driving new business revenue and protecting margins.”

The study was based on an online survey of 217 decision-makers responsible for sourcing electronic components at global manufacturers across high-tech, industrial equipment, automotive, aerospace and medical device companies with 500 or more employees.

“Risk does not exist solely in post-product release endeavors,” the companies report. “Eighty percent of the lifetime risk and cost of a typical hardware product is decided during that product’s initial design. Companies need to examine what’s happening in the design phase because that’s where the disconnect often exists.”

Survey Says…

According to Dimensional Research and Supplyframe, 91% of respondents indicated that sourcing issues are the cause of product launch delays. An even greater share (95%) of the survey group agreed that the path to solving component sourcing issues requires integration of engineering, sourcing, finance and supply chain teams, including external partners. “This points to the importance of de-risking design as early as possible in the design cycle,” the companies conclude.

“New product introduction—NPI—is never easy, but the shortages experienced during the coronavirus pandemic have created a new set of challenges for manufacturers across the globe,” said Supplyframe’s Steve Flagg in a press release.

“This experience puts greater emphasis on the importance of building resilient supply chains,” he continued. “That starts in the product design phase with a connected NPI process—enabling effective collaboration across sourcing, engineering, and manufacturing by injecting prescriptive intelligence at every decision point.”

More Collaboration, Please

The new study also highlights the broad effects of the COVID-19 pandemic. In addition to the related product launch impacts, 37% of companies surveyed said their overall component costs have increased. The same share said they are unable to fill customer orders. Nearly as many (35%) said they need to rework products to replace components that are no longer available.

COVID-19 is just one contributing factor to these challenges. Other prevalent factors include:

- Global supply chain complexity

- Inadequate enterprise systems

- Limited collaboration between internal engineering and sourcing teams during new product design.

“The lack of collaboration can add to costs, lead to product launch delays, and expose manufacturers to greater market risks,” the companies point out. “It can also jeopardize the reputation and success of engineering and sourcing professionals.”

Other Key Findings

The survey also found that:

- Seventy-nine percent of the survey group said that collaboration issues have caused product introduction delays, which slows time to revenue.

- Sixty-two percent of this group said delays happen occasionally, and close to a fifth (17%) of them said they occur frequently.

- Meanwhile, 85% of the total survey group said engineers select components that can’t be effectively sourced, which could be related to inaccurate market intelligence.

- The inability to consider accurate lead times leads to greater costs for manufacturers—a whopping 81% of the survey group said they have been forced to make expensive spot buys because of component availability issues.

“Uncertainty and complexity are constants in business today. But global manufacturers have more control of managing their electronics sourcing risk than they may realize,” Flagg said. “Risk does not exist solely in post-product release endeavors. Eighty percent of the lifetime risk and cost of a typical hardware product is decided during that product’s initial design. Companies need to examine what’s happening in the design phase because that’s where the disconnect often exists.”